Powder Coating Services

Powder Coating Done Right

It’s our specialty.

Powder coating is a type of surface coating that is applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and powder coating is that the powder coat does not require a solvent to keep the binder and filler parts in a liquid suspension form. Our custom powder coating is typically applied electronically and is then cured at high heat in an oven to allow it to flow and form a “skin”. The coating creates a hard finish that is thicker, tougher, and longer-lasting than conventional paint.

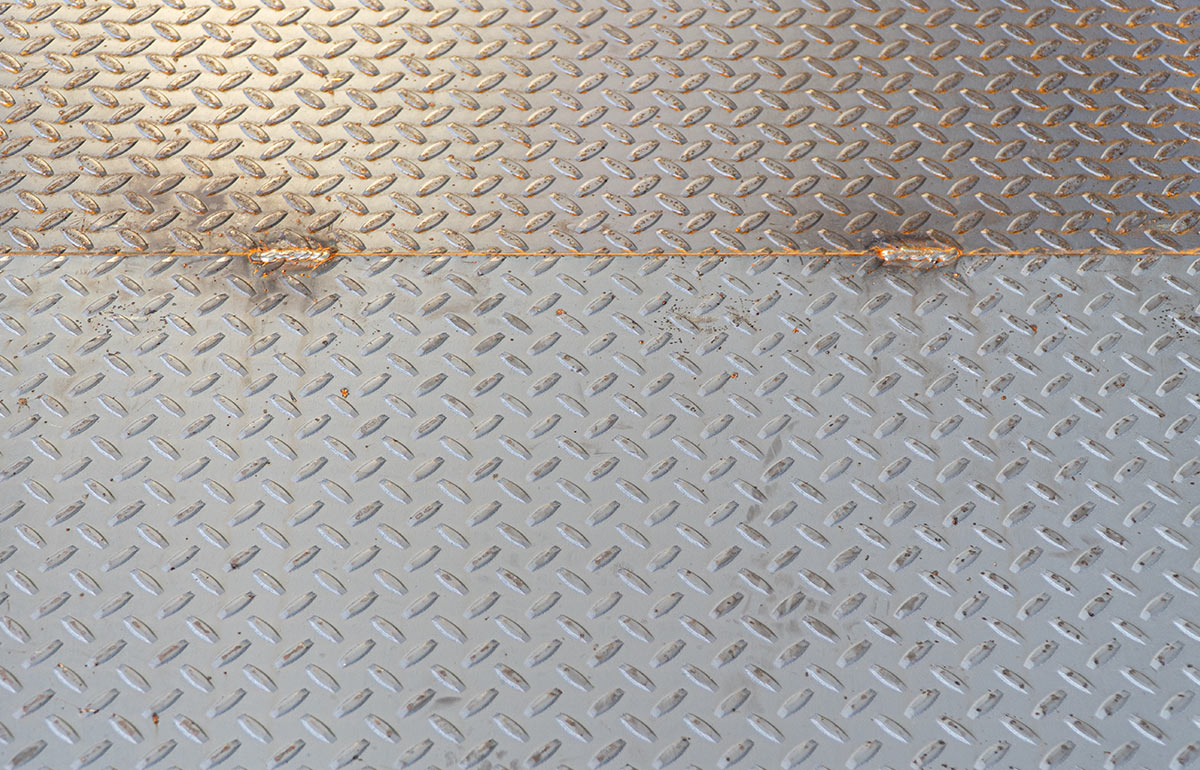

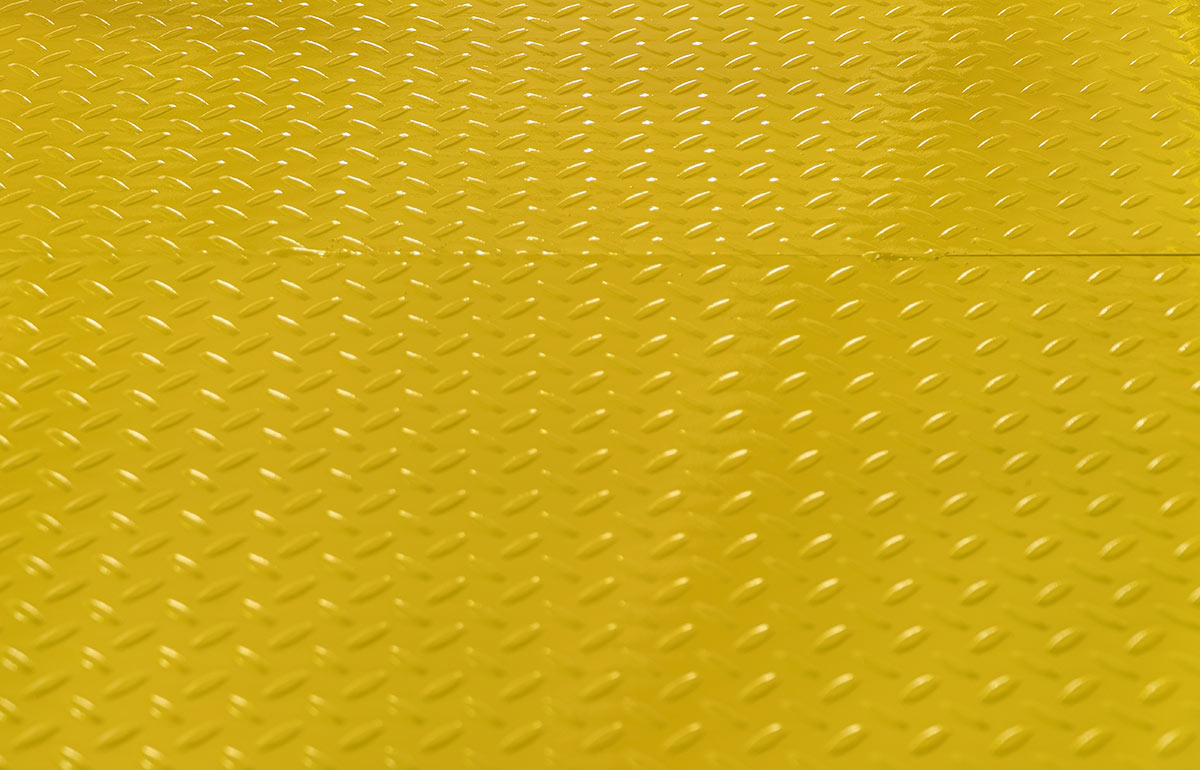

Before & After Powder Coating

Slide the circle left and right to see before and after powder coating.

0

Employees

0

Stock Colors

0

Square Foot Facility